The fish processing industry is a dynamic and ever-evolving field that plays a vital role in meeting global seafood demands. As consumer expectations for quality and sustainability grow, so does the need for advanced, efficient, and reliable machinery. The latest innovations in fish processing are not only enhancing productivity but are also revolutionizing the way fish are prepared, packaged, and delivered to markets around the world.

From automated gutting and precise filleting to intelligent grading and state-of-the-art packaging, modern machines are setting new standards in the industry. This article will delve into the leading fish processing machines in today’s market, showcasing the technologies that are shaping the future of seafood production.

This article was prepared using materials provided by Normar Trading AS (https://www.normartrading.no), a company specializing in the selection and sale of fish and meat processing equipment.

1. BAADER 144 – Gutting Machine

The BAADER 144 represents a specialized gutting machine designed for handling various types of fish. Efficiently performing gutting operations, it ensures a clean and precise cut, minimizing waste. Its adaptability allows handling different sizes and species of fish, often utilizing advanced sensor technology to adjust the cutting parameters. Maintenance and hygiene standards are well considered, providing a user-friendly interface and complying with industry regulations.

2. Marel SensorX – Quality Detection System

Marel’s SensorX system stands out for its advanced quality detection capabilities. Utilizing X-ray technology, it identifies and removes unwanted contaminants such as bones, metal, or stones. Its intelligent software allows customization of quality parameters, ensuring that only products meeting the desired quality standards proceed to packaging. Integration with other processing lines makes it an indispensable tool in modern fish processing.

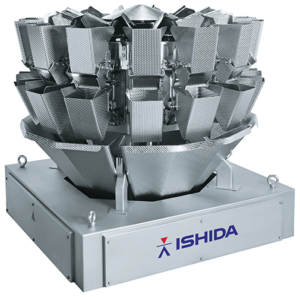

3. Ishida Weighing Systems – Multihead Weigher

Ishida’s multihead weighers are renowned for their accurate weighing solutions in the fish processing industry. Designed for high-speed performance without compromising precision, these machines can handle various products, including fresh, frozen, or processed fish. Their intuitive design enables easy cleaning and maintenance, while their software offers extensive data analysis for optimal production control.

4. Optimar STETT – Fish Grading System

Optimar’s STETT fish grading system provides an automated solution for grading fish based on size and weight. Through a combination of conveyors, sensors, and intelligent software, it streamlines the sorting process, maximizing throughput and ensuring uniform product quality. Its modular design allows scalability, meeting the needs of different production volumes and types of fish.

5. Baader 200 Heading Machine

The Baader 200 is a leading heading machine, known for its efficiency in removing heads from various fish species. With its specialized cutting blades and adaptable handling mechanisms, it offers high precision and speed, reducing labor costs. Safety and sanitation are prioritized, with easy-to-clean surfaces and user-friendly interfaces, aligning with the industry’s best practices.

6. Arenco GFA-241 – Filleting Machine

Arenco’s GFA-241 filleting machine is renowned for its precision in filleting various types of fish. Its design focuses on minimizing waste and maximizing yield, with adjustable settings to handle different fish sizes. The machine’s structure ensures easy access for cleaning, following industry hygiene standards.

7. Uni-Food Technic A/S – Pinboning Machine

Uni-Food Technic’s pinboning machine offers advanced solutions for the removal of pin bones from fillets. The conveyor belt design combined with specifically engineered cutting tools ensures the gentle and precise removal of bones. It’s designed for both small-scale and large-scale production, offering flexibility in processing.

8. Kaj Olesen A/S – Grading Machine

The grading machines from Kaj Olesen provide efficient solutions for sorting fish based on weight, length, or thickness. With options for manual or automatic feeding, they offer scalability for different production needs. These machines are known for their reliability and ease of use, supporting various types of fish.

9. STEEN ST111-Skinning Machine

The STEEN ST111 skinning machine offers optimal skinning solutions for both whitefish and oily fish. Its unique design ensures minimal meat loss while providing a smooth finish. The easy adjustment features and high-quality construction materials make it a popular choice in the industry.

10. Curio M1601 – Portioning Machine

Curio’s M1601 portioning machine stands out for its ability to create uniform and precise portions from fillets. Using laser and vision technology, it assesses the shape and size of the fillets to cut exact portions. This enhances productivity and ensures consistent quality, aligning with the requirements of modern fish processing plants.

By focusing on the core technologies shaping the fish processing industry, this article highlights the machines that represent the cutting edge in the field. Understanding these machines and their capabilities is crucial for anyone engaged in fish processing, whether a seasoned veteran or a newcomer looking to establish themselves in this growing industry.